Product Information:

1. The device is based on rice (paddy) as raw material, after hydro-thermal treatment, such as cleaning, soaking, cooking, drying, etc. Then according to the conventional rice milling processing method to process rice products, with high value of nutrition, good quality, high come out rate, high oil recovery, long storage life, and short cooking time, etc.

2. The parboiled rice include two parts: parboiling part and rice milling part;

And the processing technology is pre-cleaning----destoning----soaking----steaming and cooking----drying----husking----paddy separating----milling----polishing----grading---color sorting----packing in bags. We can provide from 10t/d to 300t/d complete parboiled rice mill machine(10t/d, 15t/d, 24-30t/d, 50t/d, 60t/d, 80t/d, 100-120t/d, 150t/d, 200t/d, 300t/d) and offering installation services to your country.

3. Process details of parboiled rice milling machine:

1) Cleaning

Firstly, the paddy need to be cleaned in this stage. The paddy must be removal the dust and impurity. Through the screen, the paddy will be cleaner when remove the straw and leaf, ad other impurity, such as stone and so on.

2) Soaking

a. This stage is aimed to make the paddy absorb enough moisture, which need to be above 30%. And it will create a good condition for the starch dextrinization.

b. According to the rice variety and quality is different, usually the soaking temperature is 55-70 degrees, and soaking time is 3.5-4.5 hours.

3) Steaming

The water vapor with a certain temperature and pressure heated to the paddy, so that starch dextrinization. This operation has a great influence to the parboiled rice finished product quality, color and taste, it can increase the strength of the grain, increase the rate of rice, and change the rice storage characteristics. By adjusting the cooking process conditions, can produce color for the light, sub-dark, and dark steamed rice.

4) Drying and Cooling

This is aimed to reduce the moisture to increase production ratio and easy to store and transport.

5) Husking

Using the rubber roller to husking, the separator to separate the brown rice. And the gravity paddy will separate again, then un-husking paddy will return to the husker to again husking. The brown rice conveyto the rice whitener and polisher.

6) Milling

By using blowing rice miller to increase the rotating speed of rice miller,

7) Grading and Polishing

a. Through the rice grade, the broken rice will be separate out and the whole rice will be grade on the size.

b. Through the polisher, the rice will get better quality. And after the whitening process, the rice can be stored longer.

8) Color Sorting

Get rid of the heterochromatic granules in the rice.

9) Packing

The processing rice can be packaged in different weights and formed finished rice on the market demand.

4. Main machines:

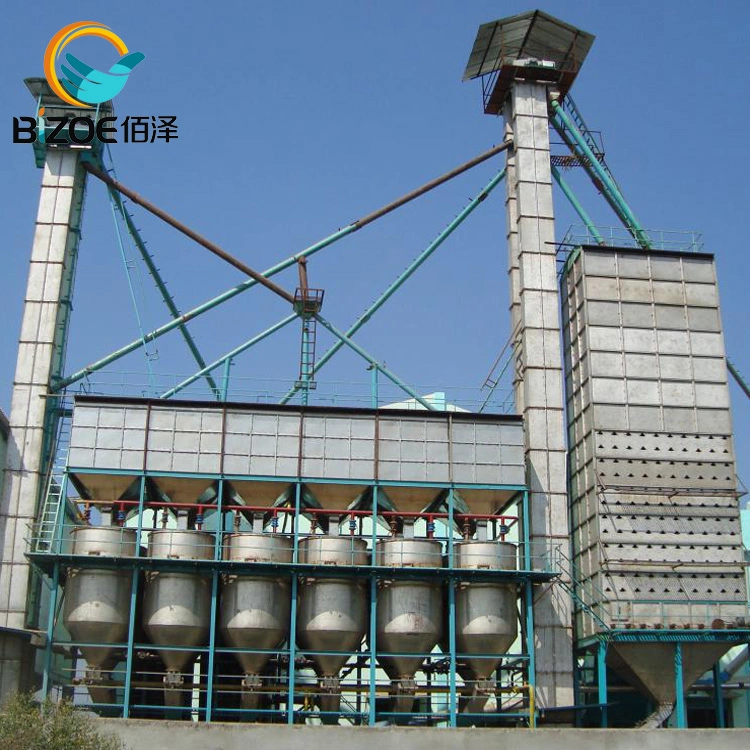

Pictures of parboiled rice mill machine:

Our customers:

Pictures of finished rice products:

Our Company:

Zheng Zhou Baize Machinery and Equipment Co.,ltd is a manufacturer of rice processing machines. We can supply 5-300ton/day complete rice mill line(Parboiled rice line) and different kinds of rice processing machines like husker,destoner, rice grader, color sorter, paddy dryer, etc. Our rice equipment have been exported and installed in rice successfully in Nigeria,Thailand, India, Sri Lanka, Indonesia and so on. Our main markets cover Africa (such as Nigeria, Ghana,Cameroon, Gabon and so on), Europe, America.... Welcome to visit our factory!

1) 5-300TPD rice milling line

2) 10-150TPD Parboiled rice milling line

3) 5-300TPD Maize flour processing line

4) 5-300TPD Wheat flour processing line

5) 5-24TPD Cassava strch processing line

6) 5-24TPD Cassava flour processing line

7) 1-24TPD Garri processing line

8) 5-24TPD Potato starch processing line

9) 5-24TPD Yam flour processing line

10) 1-20TPD Plantain flour processing line

Our service:

| Pre-sale service of parboiled rice milling machine | 1) Accept customer consultation, We will offer solutions according to customer requirements, determine the scale of operation; 2) To provide customers with project design, process design, suitable for your machine equipment plan formulation of choose and buy, in a timely manner to provide customers with related technical documents;According to your special requirements, design and manufacture of products, for your training technical operation personnel for preliminary design and construction design. |

| Serve for sale of parboiled rice mill machine | 1) The company sent technical personnel to the scene of the on-the-spot guidance equipment installation, debugging and training operators. 2) 24 hours telephone service 0086-15638177681, holiday service as usual. |

| After-sales service of parboiled rice mill machine | 1) Phone support: refers to the customers in the use of equipment of difficult problems in the process or equipment in abnormal state, by telephone or by fax to the company for technical support and help.Company after confirm the customer's service request, will arrange technical personnel within the prescribed period of time (i.e., response time) by phone to help fault locating the demand side, and put forward solutions, guide customers to exclude equipment failure in the end. 2) If you can't fault diagnosis by phone and solve the failure phenomenon, will immediately send technicians to the scene, eventually to solve. 3) The company's products provide a year warranty, life-long maintenance. |

FAQ:

1. Can I only buy only the parboiling machine or rice milling section?

Yes, you can buy only parboiling machine or rice milling machine or complete parboiled rice mill machine.

2. Are the engineers available to overseas to install for us?

Yes, our enigneers will come to your factory to guide the install and train your staffs.

3. How long is your warranty?

Our warranty time is 3 years. During warranty time,we will send engineers to repair for you if anything wrong happens.

4. What's the power type of the paddy parboiler and drying machines?

We have diesel, gas, wood, coal type etc, we can also customized it for you based on your requirements.

High quality machine, best price and good after-sale services for you!

--- Zhengzhou Baize Machinery and Equipment Co., Ltd.