What can we do:

1.Provide all kinds of oil machine: mini oil plant, oil extraction mill, oil refinery machine, small oil factionry mills, large oil processing line, etc.

2.Single oil machine and turnkey oil processing project are both available.

3.Oil plants include: coconut oil machine, palm oil mill, sesame oil plant, soya bean oil machine,rice bran oil extraction machine , peanut groundnut oil plant, rapeseed oil machine, corn germ oil machine and othervegetable oil plant.

4.Custom design for household oil machine and oil factory turnkey project with installing and adjusting.

Requirements for extraction cake ,steam ,water. electricity etc for rice bran:

| Moisture of extraction material | 5-8% |

| temperature of extraction material | 50-55°C |

| oil content of extraction material | 50-55°C |

| oil content of extraction material | 14-18% |

| thickness of extraction cake | less than 13mm |

| powder porosity of extraction material | less than 15% (30 mesh) |

| steam | more than 0.6Mpa |

| solvent | national standard No. 6 solvent oil |

| electric powe | 50HZ 3*380V±10% |

| Electric lighting | 50HZ 220V ±10% |

| tempreture of supplement water | less than 25°C |

| Hardness | less than 10 |

| volume of supplement water | 1-2m/t raw material |

| temperature of recycle water | less than 32°C |

Three steps in the treatment of rice bran oil:

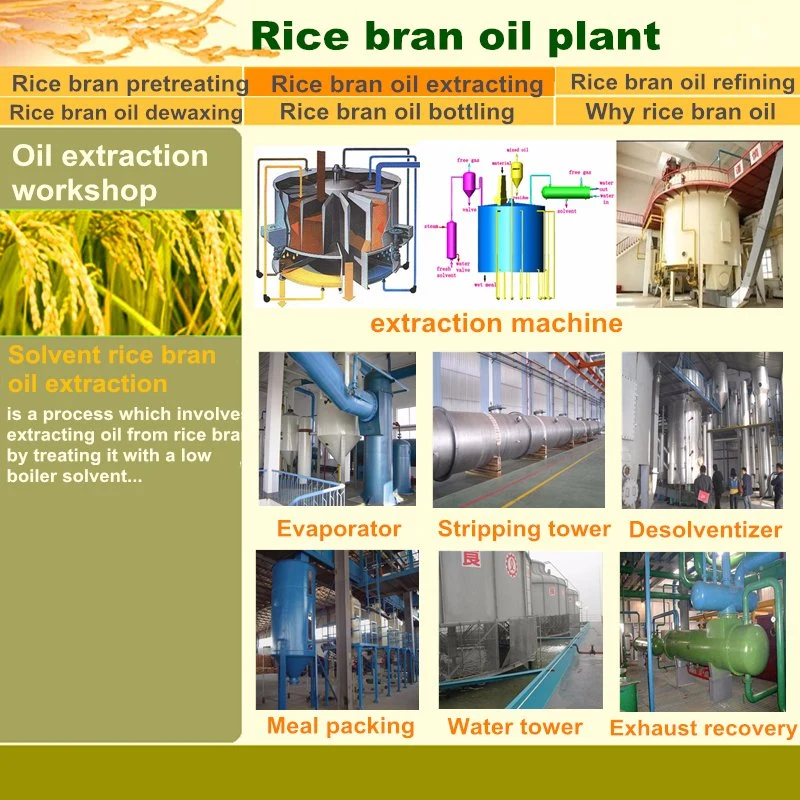

(The whole production line contains three workshops: rice bran pretreatment&expansion workshop, rice bran extraction workshop,rice bran oil refining&dewaxing workshop)

1.)Crude rice bran → cleaning → softening → expanding → drying → to extraction workshop

2.) solvent steam

↓ ↓

extraction → mixed oil → evaporation→ steam-stripping → crude rice bran oil

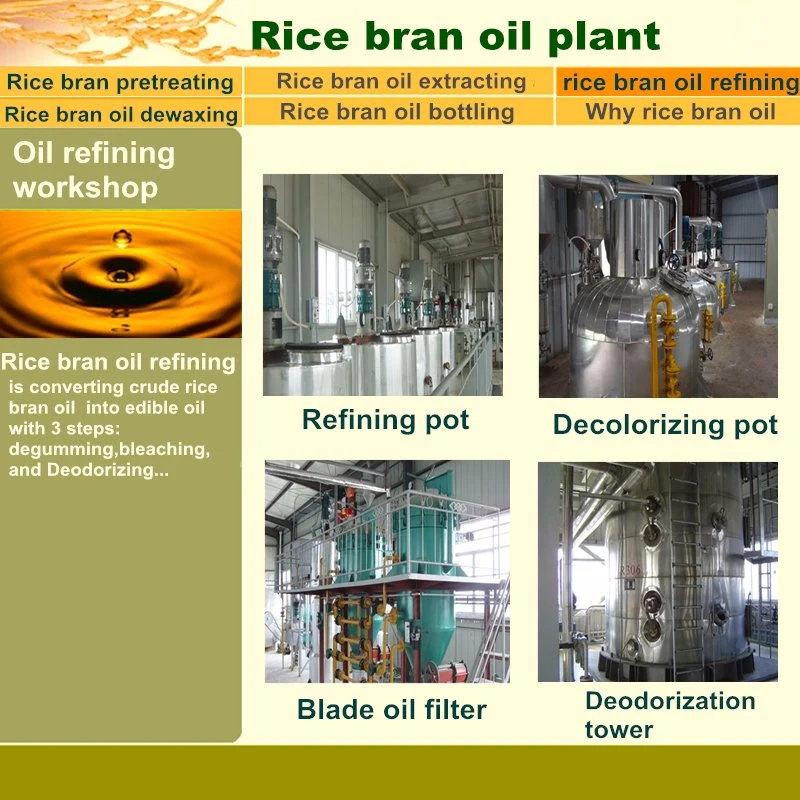

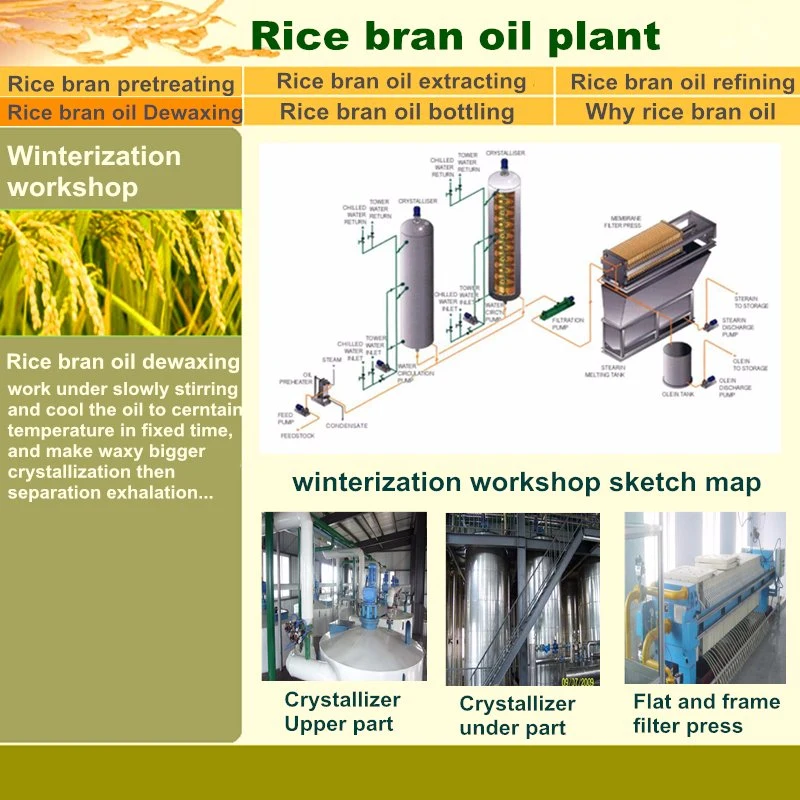

3.)crude rice bran oil → degumming&dephosphorization → deacidification → drying → decolorization → deodorization → defatting → dewaxing → product oil

The simple processing of oil pretreatment includes pressing, high temperature pressing, cold pressing (less than 70 degrees) etc.

1,Formal oil pressing can adopt one time or twice pressing of oilseeds. It is applicable for low capacity required oil processing oil plant.

2,High capacity oilseeds pretreatment and oil pressing equipped with oil extraction treatment, is used in high capacity and large-scale oil pressing plant, or high oil content oilseeds processing plant.

3,Oil prepressing can get up 70% oil fat of embryo, and residual oil inside pre-pressed cake can be extracted by organic solvent.

Quality requirements of oil refinery for Rice bran oil:

1,moisture and volatile matter of crude oil: less than 0.25%;

2,impurity content of crude oil: less than 0.2%,

3,acid value of crude oil(mgkoh/g): less than 7.

Quality and Service Commitment:

Our company always put the interests of customers and product quality of the first place, and always adhere to the" no best, only better" as our purpose. We will be commitment to provide high quality products with perfect site services and after-sales service. Now the specific commitments as follows.1. Ensure to timely provide complete sets of equipment and accessories.

2. Ensure that one-time installation and debugging guiding acceptance.

3. To provide high quality material with preferential price.

4. Priority to provide customer our new craftmanworks and products.

5.Free training technological operator to ensure the trained staff can independent operation.

6.In the installation process, we will appoint 1-5 installation supervision staffs on spot. we will offer an experienced project manager, to guiding your installation and debugging and training your workers.

7.After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, on-line debugging and Feeding trial operation ,to ensure that equipment can normal operate in full load conditions. We will provide all kinds of information and records according to the requirements of the bid. The qualified completion files will be provided to customers according to their requirements within one month after acceptance.

Packaging & Shipping

(1) Standard container export standard container ,wooden case,or as customer requirements.

(2) By air, by train or by sea, you can choose it according to needs, meanwhile we will give our best suggestions based on our experience.

(3) We will fast delivery.

(4) We will supply the full feedback when your machine is on the way.

FAQ:

(1) Question: How long can you guarantee your products and spare parts?

Answer: we promise to repair, change or withdraw our products or supply the spare for free within a year if there are some quality issues. After one year, we also can provide technical and other supports during the whole life of our products whenever you need.

(2) Question: How about your company strength?

Answer: we have accumulated nearly three decades of experience in producing and sales on oil press machine equipment, which helps us to through a number of national certifications and occupy so many markets, that not only domestic but also international.

(3) Question: What's your biggest advantage?

Answer: Obviously, it is professional and dedicated.