1. Product Description

MLHQ series new type of paddy husker is a new generation of husker developed by our company based on the absorption and digestion of foreign advanced concepts, combined with the traditional paddy husker mature paddy separation system. In the past decades, the structure of gear shifting by gearboxes has been used for decades. With the emergence of more mature and reasonable drive control methods, the development of rubber roller husker has made new breakthroughs. Through years of practice, it has been proved that the performance and technical indicators of this series of hullers have greatly improved compared to traditional huskers.

2. Feature

1. Large output, high shelling rate, low broken rice rate, stable operation and low noise.

2. High degree of automation

(1) Automatic detection, automatic opening of door and merging roller when there is material.

(2) Rubber roller wear is automatically compensated during processing

(3) Automatic detection, automatic loosening and closing the material door when there is no material

3. Stepless adjustment of tight roller pressure, suitable for raw grain processing in different regions.

4. Perfect motor overload protection function, equipment operation is more reliable.

5. Simple operation, individual operators can easily replace the rubber roller.

3. Technical Parameter

Model | Capacity (T/H) | Power (Kw) | Size (L*W*H) Mm |

MLHQ10 | 4~6 | 7.5kw+4kw+120w | 2100×1600×2800 |

MLHQ10H | 4~6 | 7.5 | 1000×750×1400 |

MLHQ10B | 4~6 | 4.0 | 2100×1600×1400 |

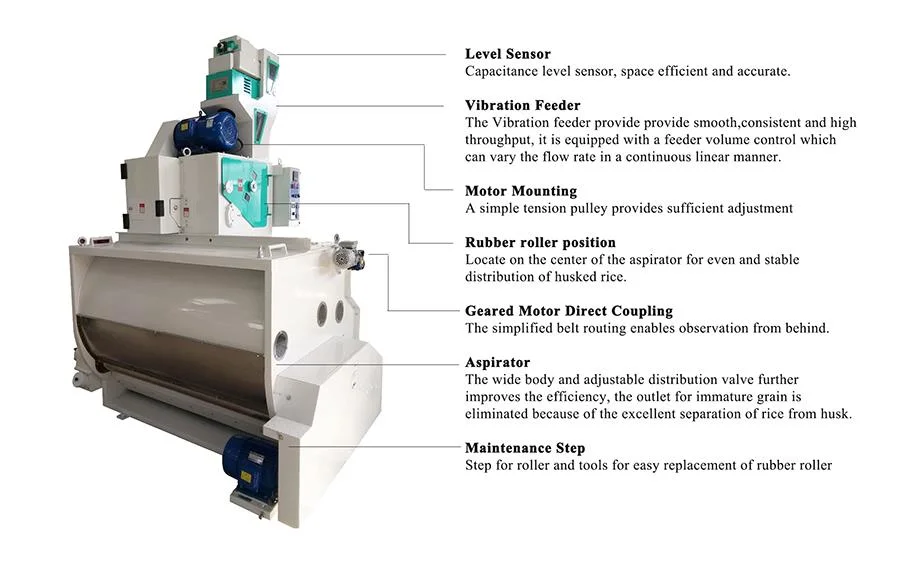

4. Working Principle

Process flow:

The material enters the hopper of the husker, and the feeding gate and vibration feeder are controlled by the level sensor, and the material is conveyed into the long flow plate of husker, and the material is evenly fed into Shelling is performed in fast and slow rolls. The hulled grain, brown rice, and shell mixture falls into the lower box through the homogenizing plate, and is sent to the air channel through the lower drain plate. The brown rice is separated from the shell by air selection, and the husk enters the large channel through the vertical air channel. The rough grain mixture is discharged from the discharge port into next process.

5. Product Picture.

Packing Delivery

Our Service

[Consulting Service] Our consultant provides you with pre-sales expertise consulting services, system evaluation, providing the best engineering solution

[Engineering Service] Set up special project team of technical, installation and sales for you. to design, install and commissioning a complete set of equipments, whole process tracking service.

[Training Service] Our experts in technology and management provide you long term production, operation, management, maintenance and other professional skills training, to help you train operation, technology, management personnel.

[Spare Part Service] We provides high-quality and reliable original accessories. And the service centers also keep store of a certain number of common accessories to meet the demand of rapid supply.

[Site service] Our service engineer goes deep into your site to solve practical problems. Conduct on-site training on the use of products and seek for improvement of a new way of thinking and method to reduce cost and increase efficiency.

FAQ

1. What is the delivery time of this machine if we book order right now?

We will deliver your order within 30-60days depend on different of machines.

2. How do you pack this machine for exporting?

We will provide packing which is suitable for the agreed means of transportation and for the foreseeable conditions of storage at the destination.

3. How can we make inspection before delivery?

We welcome you send your inspection manager come to our factory for inspection or you can nominate international the third part inspection company.

4. What is the warranty for your machine?

If any defect or non-conformity arising from faulty design, materials, we shall eliminate defects or replace machine.

5. What is the installation requirement of this machine?

The foundation of the machine should be with sufficient strength to support the weight of the machine.

There should be enough space around the machine for maintenance and inspection.

Hot Tags: MP-B automatic feeding rice polisher, China, manufacturers, suppliers, factory, price, pricelist, quotation, buy discount