Product Description

High-quality rice mill plant include a series of continuous production sets that work from cleaning, husking, rice and paddy separation, polishing of rice, grading. The whole set is composed if some main equipment such as pre-cleaner, de-stoner, paddy husker, paddy separator, emery roll whitener, air-jetting iron roll whitener, whitener, white rice plansifter, water mist rice polisher, color sorter, and some other assistant devic such as magnetic separator, winnowing, transportation, electric control, end product warehouse and other vacuun packing machine, rice husk adsorption, rice bran system.

The equipment is mainly apply to produce high precision rice and various apply to preduce high precision rice and various grades. The rice whitener work with multi-machine lightly grinding process, the processed top grade rice shoe to be luminous and contain less bran. The combination from including flat land installment and the tower installment.There are various kinds of output, to say daily production as 30TPD, 40TPD, 50TPD, 80TPD, 100TPD, 200TPD, 300TPD, 500TPD, 1000TPD and etc.

Specification

| Pre Cleaning | Removing all impurities and unfilled grains from raw paddy |

| De-stoning | Separating small stones from paddy |

| Husking | Removing husk from paddy |

| Husk Aspiration | Separating the husk from brown rice/ unhusked paddy |

| Paddy Separation | Paddy Separation |

| Whitening | Removing all or part of the bran layer and germ from brown rice |

| Polishing | Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of milled kernel |

| Color Sorting (Optional) | Removing foreign materials such as colored, broken, immature and insected grains from milled rice |

| Length Grading | Separating small and large brokens from head rice |

| Blending | Mixing head rice with predetermined amount of brokens, as required by the customer |

| Weighing and Bagging | Preparing the milled rice for transport to the customer |

Equipment List

a. Vibratory Cleaner

b. Gravity Stoner

c. Paddy Husker

d. Paddy Separator

e. Rice Whitener

f. Rice Grader

g. Rice Polisher (optional)

h. Color Sorter (optional)

i. Packing Scale (optional)

More Options

| Parboiling (Optional) | Improving the nutritional quality and milling recovery percent during husking and polishing / whitening operation |

| Paddy Dryer | Drying raw paddy with high moisture |

| Thickness Grader | Removing broken and immature grains from brown rice before whitening |

| Flow Scale | Flow controlling and incontinuous accumulating measure of white rice |

| Hammer Mill | Milling chaff into grainy materials |

| Rice Hull Separator | Separating paddy and broken brown rice from husk |

| Bran Separator | Separating broken rice from rice bran |

Detailed Pictures

Company Information

Customers' Visit

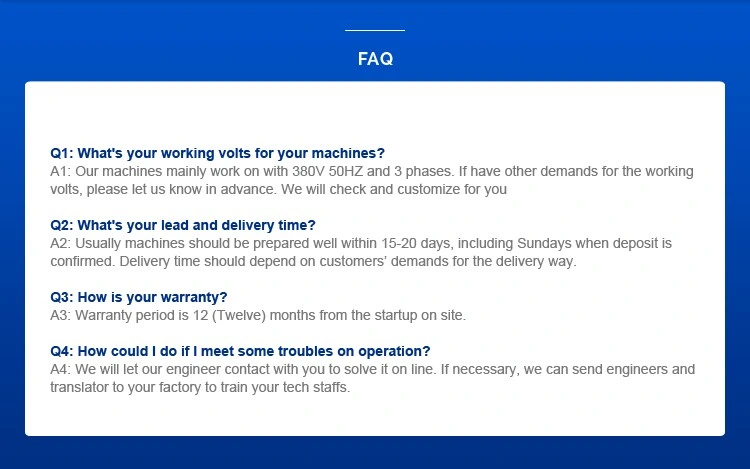

FAQ

How to Order

Contact Your Sales