High Quality Vacuum Hydraulic Oil Filter For Emulsified Oil Clean

Applications

1.This machine is applied to purify lubricating oil, Hydraulic oil, Turbo oil, Coolant oil, Engine oil, Trucks oil, Mechanical oil, Heat treatment oil, Gear oil etc.

2.TYA oil purifier can be also used for treating some other oil such as used Cooking oil, Vegetable oil (Pretreatment or Post-treatment for producing bio diesel), etc. TYA is widely used for various industries such as the mine, metallurgy, electric power, transportation, manufactures etc., where need to maintain lubricating systems.

Function

TYA can effectively remove gas, water, impurities and other contaminants from oil, and strongly emulsified, by which to reduce oil's water content and impurity content, improve oil cleanness.

After treatment, the oil's technical parameters and properties are improved, prolonging oil service life and ensuring safety operation of industrial equipment.

Features

1.With the strong ability to filter the impurity, which can filter the particles complete TYA.

2.It has the back flush system, which can clear impurities automatically TYA.

3.Advanced dielectric condensation device

4.This machine installs the new pressure protector, which can control the temperature automatically TYA; also it can drain water on line by the w

ater-separator device. So it is easy to control this machine.

5.We adopt the high quality filter materials, which has a good function in precision of eliminates impurity is high and the service life is long. Also, it has a large volume for storing the impurities.

6.The unique degas and dewater system: Using the Stereo-Evaporation technical, which can separate the water and gas from the oil quick TYA by the Multi-level water-oil separation technology

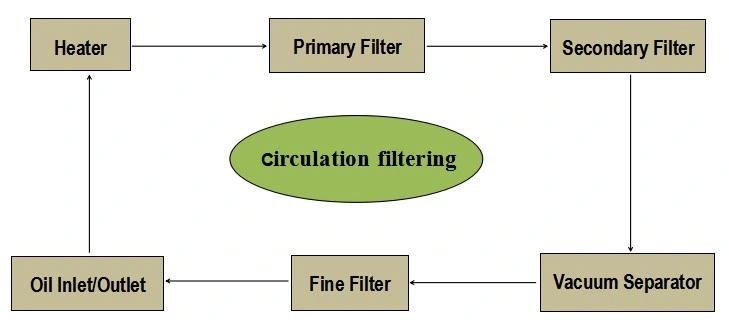

Working Principle

When TYA starts working, oil will be sucked into heater by vacuum pressure, then the oil will be heated and flow into primary filter, where the big impurities are separated. then, oil flows into vacuum separator, and flows through a special designed device, which makes per unit volume oil to produce a large surface area, lets the oil exposure in low humidity atmosphere, so the gas and water are separated from oil. the gas and separated water vapour forms as mixed gas, flows through water tank and cooler, condense into liquid and flows into water receiver, the residual gas is exhausted by vacuum pump. Oil flows through oil pump and into fine filter, where the tiny impurities are separated. If the oil is very dirty, or is high water content etc., you can purify the oil circularly for several times, by which to remove the water and impurities completely.

Technical Parameters

Applications

1.This machine is applied to purify lubricating oil, Hydraulic oil, Turbo oil, Coolant oil, Engine oil, Trucks oil, Mechanical oil, Heat treatment oil, Gear oil etc.

2.TYA oil purifier can be also used for treating some other oil such as used Cooking oil, Vegetable oil (Pretreatment or Post-treatment for producing bio diesel), etc. TYA is widely used for various industries such as the mine, metallurgy, electric power, transportation, manufactures etc., where need to maintain lubricating systems.

Function

TYA can effectively remove gas, water, impurities and other contaminants from oil, and strongly emulsified, by which to reduce oil's water content and impurity content, improve oil cleanness.

After treatment, the oil's technical parameters and properties are improved, prolonging oil service life and ensuring safety operation of industrial equipment.

Features

1.With the strong ability to filter the impurity, which can filter the particles complete TYA.

2.It has the back flush system, which can clear impurities automatically TYA.

3.Advanced dielectric condensation device

4.This machine installs the new pressure protector, which can control the temperature automatically TYA; also it can drain water on line by the w

ater-separator device. So it is easy to control this machine.

5.We adopt the high quality filter materials, which has a good function in precision of eliminates impurity is high and the service life is long. Also, it has a large volume for storing the impurities.

6.The unique degas and dewater system: Using the Stereo-Evaporation technical, which can separate the water and gas from the oil quick TYA by the Multi-level water-oil separation technology

Working Principle

When TYA starts working, oil will be sucked into heater by vacuum pressure, then the oil will be heated and flow into primary filter, where the big impurities are separated. then, oil flows into vacuum separator, and flows through a special designed device, which makes per unit volume oil to produce a large surface area, lets the oil exposure in low humidity atmosphere, so the gas and water are separated from oil. the gas and separated water vapour forms as mixed gas, flows through water tank and cooler, condense into liquid and flows into water receiver, the residual gas is exhausted by vacuum pump. Oil flows through oil pump and into fine filter, where the tiny impurities are separated. If the oil is very dirty, or is high water content etc., you can purify the oil circularly for several times, by which to remove the water and impurities completely.

Technical Parameters

| Item | Unit | TYA-10 | TYA-20 | TYA-30 | TYA-50 | TYA-100 | TYA-150 | TYA-200 | TYA-300 |

| Flow rate | L/Hr | 600 | 1200 | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 |

| Vacuum degree | Mpa | -0.06 ~ - 0.095 | |||||||

| Working Pressure | Mpa | ≤0.4 | |||||||

| Temperature Degree | ºC | 0 ~ 100 | |||||||

| Power Supply | 380V,3phase, 50HZ (or as required by customer) | ||||||||

| Working noise | DB (A) | ≤75 | ≤75 | ≤75 | ≤78 | ≤78 | ≤78 | ≤80 | ≤82 |

| Electric heating Power | KW | 18 | 18 | 24 | 30 | 54 | 72 | 90 | 120 |

| Total electric Power | KW | 19.3 | 19.3 | 25.65 | 32 | 57.1 | 79 | 98 | 130 |

| Inlet (outlet) Caliber | mm | Ф25 | Ф25 | Ф25 | Ф32 | Ф42 | Ф50 | Ф50 | Ф60 |

| Size | mm | 1260 x900 x1500 | 1260 x900 x 1600 | 1500 x1050 x1650 | 1600 x1150 x1700 | 1750 x1250 x1800 | 1900 x1600 x1950 | 1900 x1700 x2000 | 2100 x1700 x2100 |

| Weight | Kg | 450 | 550 | 600 | 750 | 850 | 1000 | 1200 | 1500 |

| AFTER TREATMENT | |||||||||

| Moisture (water content) | ≤ 50 PPM | ||||||||

| Gas Content | ≤0.1% | ||||||||

| Impurities Degree (Filtration precision) | ≤1 ~ 5 micron (no free carbon) | ||||||||

| Demulsification | New oil≤15min, running oil≤30mi | ||||||||

| Cleanliness | ≤NAS 1638 Grade 6 | ||||||||

Machine pictures

Company information

Packing and Delivery

Safe and Timely Transportation

Standard export wooden case with high quality cushioning material ensures that the customers get the item in good condition.

Carefully check every packing detail before delivery to avoid any troubles during the transportation.

Appointed logistics company could be used according to customers demands.

Do our best to make sure customers can get the goods in time.

Certificates

After-sales Services

1.One year guarantee for product quality. (People damaged parts are charged).

2.Lifelong maintenance and spare parts supply.

3.Free design of fixtures as customers required.

4.Free training for machines installation and operation of the staffs.

For more infomration and detailed product specifications, please contact us!

Please leave us your email and mobile number to send you more photos , brochures and price details. Thank you!

Post by Anne